Episode 204

In this very special episode, I join my friend Hope at her shop and we talk over our visit to Quiet Valley Farm, where we spent the day in period costume and learned about the harvest and preparation of flax to make linen thread. The photo series here is a companion to our description of the process on the audio episode. If you have any questions or wisdom to share, I hope that you will participate in the discussion thread on Ravelry.

Flax harvest: Quiet Valley’s extensive gardens included a small planting of flax plants. These photos also show the period clothing that Hope and I wore so that we could really take part in the hands-on activities of the day.

Here is Mr. Oiler harvesting flax. Once harvested and dried, flax can be stored indefinitely before retting and the remainder of the processing. It just needs to be kept dry and protected from rodents. Large scale flax harvesting involves stooking (tying the flax in bundles for easier handling) and rippling (removing seeds from stalks).

Something we didn’t see here, but is an essential part of processing, is retting. After the initial thorough drying of the plant, it is then retted (rotted) so that the outer fibers break away from the inner core. There are two methods of retting: dew retting, in which the flax is spread over the ground and left to wet and dry over a period of a few weeks; or vat retting, in which flax is submerged in a tub or pond. Vat retting is risky in that it is easy to overdo it and start rotting the inner core. There is also the consideration of where runoff from vat retting ends up because some of the enzymes can be harmful to farming or animal life. Another consideration is the finished product: vat retted fibers are pale in color; dew retted fiber is often brown or green in appearance.

Here we see a flax break in use. It’s a simple lever, a reproduction made by Mr. Oiler. The top is lifted and then lowered as a bundle of flax is drawn through it.

You can see the difference in the flax from the previous photo to this one as the outer pith breaks away.

You can see the difference in the flax from the previous photo to this one as the outer pith breaks away.

Next comes scutching, in which a scutching knife is used to scrape unwanted fibers away from the desirable flax.

The hackling process involves repeatedly pulling a handful of fibers over some very daunting nail combs to remove more unwanted waste and to straighten and soften the flax.

In the photo sequence above, Hope’s distaff is prepared, or dressed, with flax and tied with a ribbon to secure.

Here I am taking a turn at Hope’s wheel. Can you see the little water pail at my right knee? In this photo, I appear to have the hang of it, but mostly, I struggled to keep the wheel spinning in a counterclockwise direction to achieve the S twist that is recommended for flax singles.

Most of my spinning was on my Jenkins Aegean, a Turkish spindle.

This was my view for the afternoon: an assortment of smart and very interesting women in period dress, sharing knowledge, and working at various stages of the process.

As you may have guessed, flax processing yields much more waste than beautifully-spun linen. One of the stations was devoted to turning this waste into toe rope.

Several strands of spun toe can be plied together on this wheel to achieve various strengths of toe rope.

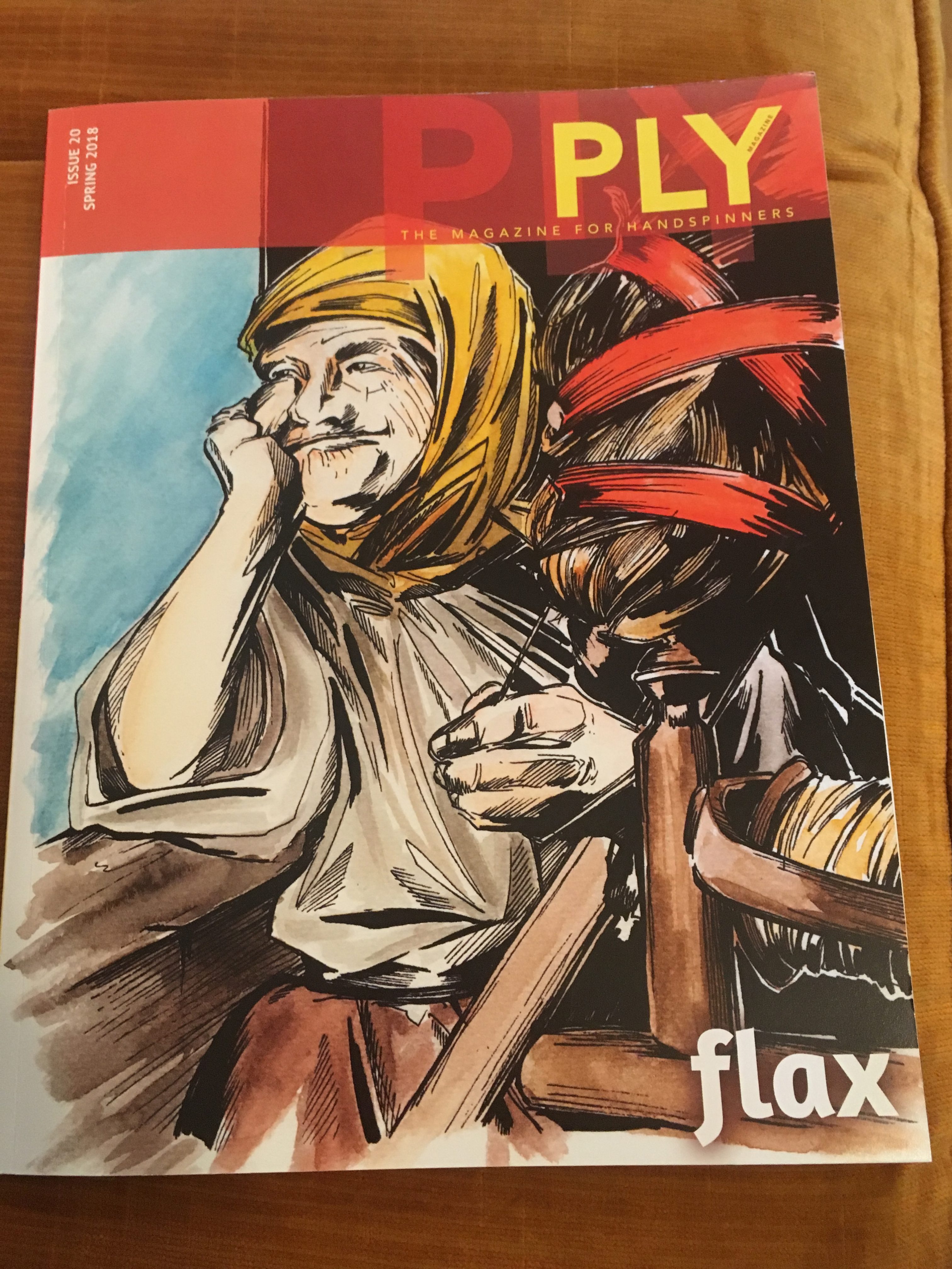

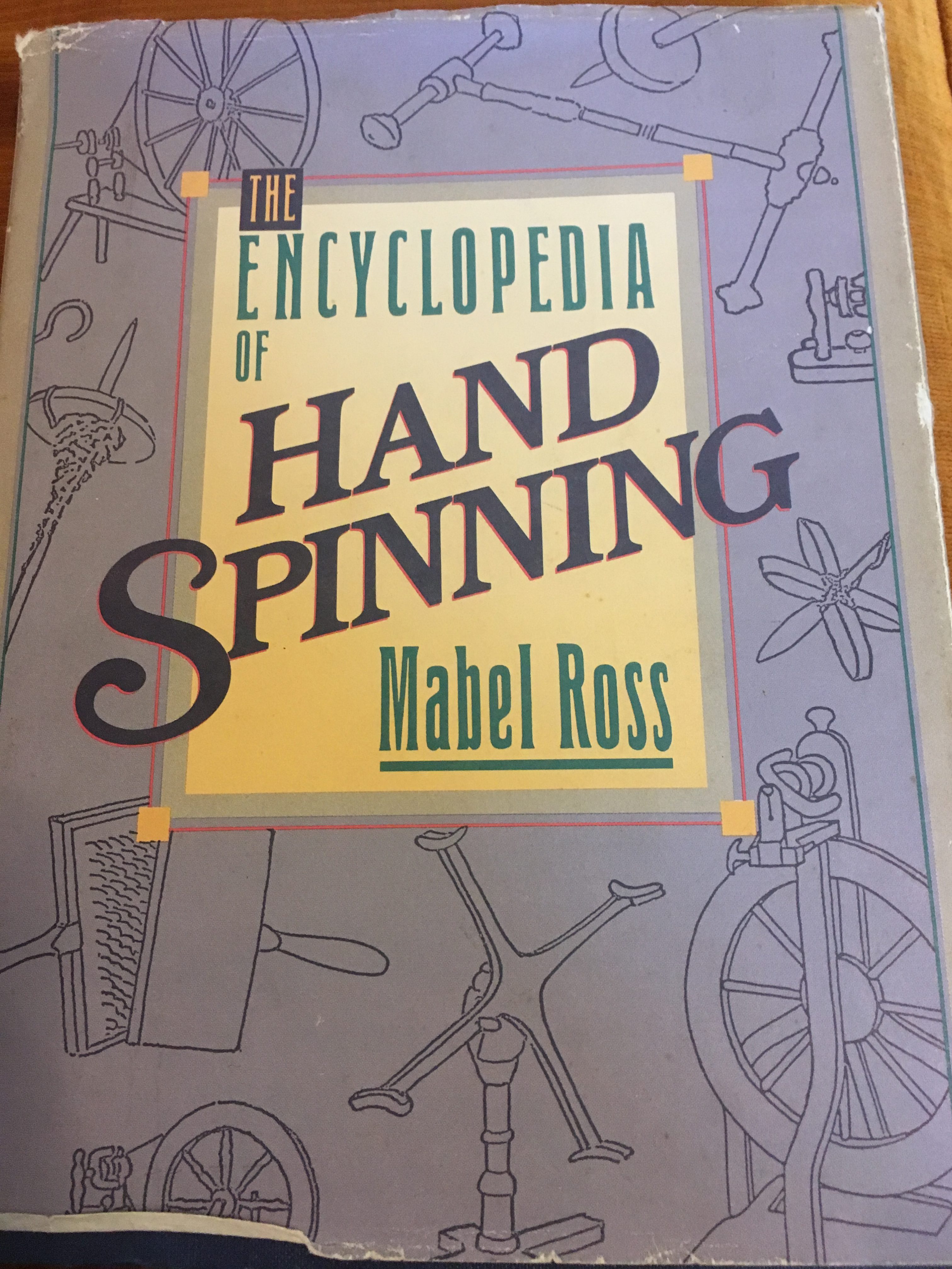

Some resources that we discussed on the episode.